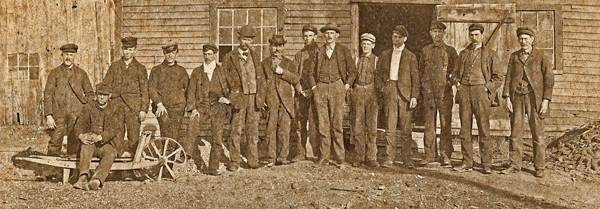

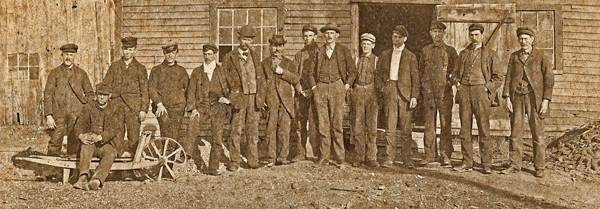

The crew at the Pleasant Street ropewalk in Castine. Photo courtesy Castine Historical Society

By Laurie Schreiber

We take it for granted, but rope has a history in Maine that’s as long as the coastline that once housed the long buildings, known as ropewalks, where lines for fishing boats and sailing vessels were made.

In Castine, a large ropewalk was built in 1830 by John Dresser, who passed it on at some point to his son, John Wentworth Dresser. The Dresser ropewalk on Pleasant Street produced cordage and rigging for sailing vessels when Castine was a thriving center of maritime commerce, boatbuilding, fishing, and ship provisioning. Like sail lofts and chandleries, ropewalks were a necessary part of any seaport.

Large sailing ships were rigged with miles of rope—a six-masted schooner contained up to seven miles, a frigate as many as twenty.

A natural product, rope decayed fairly regularly and, certainly on ships, the running rigging at the very least needed to be replaced on a regular basis, said Maine Maritime Museum Senior Curator Nathan Lipfert. “That’s a huge amount of line—miles and miles of line on larger boats.”

Ropewalks were as long as the rope that was to be produced, which could range from a few hundred feet to more than 2,000. Up until the 18th century, most were outdoors.

At one point the Castine Line & Twine Co. ropewalk on Water Street in Castine was said to be the largest single wooden building in Maine. It burned in 1913 after being struck by lightning. Courtesy Castine Historical Society Collections

The process was slow and methodical. A ropemaker wrapped hanks of raw fiber loosely around his waist and attached one end to a spinning wheel. While another person cranked the wheel, the ropemaker walked backward, pulling the fiber taut through his fingers to facilitate winding. Even tension was needed to ensure the strands formed correctly. The resulting yarns then were attached to another wheel and twisted in the other direction into thicker strands. Those strands were twisted together again into the desired rope diameter. The series of counter-twists held the rope together and gave it strength.

“All you do is take a fiber and twist it,” said National Park Service Ranger Dan Gagnon, who works at the Charlestown Navy Yard in Massachusetts, home of this country’s last remaining naval rope factory. “Twisting creates greater tensile strength than if you lay fibers next to each other.”

In the 19th century, the invention of the steam engine meant production could be mechanized within enclosed factories. The process involved bales of fiber, such as hemp and manila, both of which are resistant to rot. The yarns were dipped in molten tar to protect them further from decay. The combination of hot tar and raw fiber in wooden buildings made fires a hazard of the profession.

Raw fiber was fed to spinning machines to become yarn, which was then wound around bobbins. The end of the yarn on each bobbin was hooked to a strand-forming machine. This machine was mounted on a rail the length of the factory, traveling backward while twisting the yarns together. Laying the strands into rope involved a similar operation.

This ropewalk on Pleasant Street in Castine, built circa 1830, was near where the Maine Maritime Academy football field is today. In those days, rope was made in buildings that were as long as the line produced. Courtesy Penobscot Marine Museum

By the 1870s, the Dresser ropewalk in Castine included a head house (the head of the ropemaking building) and a long, low dilapidated building with three machines inside that were making 80 dozen lines per day, according to information from the Penobscot Marine Museum. Toward the end of the company’s operation, it specialized in fishing lines, including long trawl lines.

In 1900, Dresser sold his ropewalk to Edward H. Carpenter. Hailing from Brookline, Massachusetts, Carpenter was working at the Massachusetts Mutual Life Insurance Company at the time, according to his granddaughter, Susan Ruch of Falmouth, Maine. He renamed the company Castine Line & Twine, and built up the business, producing fishing lines in 20 sizes and selling it on both the East and West coasts. At some point, Carpenter built a new ropewalk and added machinery that doubled his output. The new ropewalk was said to be the largest single wooden building in Maine—600 feet long and three stories high, with a large storeroom over the third floor and more than 150 windows.

According to a news report of the day, the company was “engaged in the manufacture of cod and mackerel lines and supplies many thousand pounds every year to fishermen. They also make a specially prepared gangion which has a very large sale.” (Gangion is the short line on which the fish hooks are tied, all then are attached to the long lines deployed to catch fish.)

Ropewalks were as long as the rope that was to be produced, which could range from a few hundred feet to more than 2,000.

In 1913, Carpenter’s factory was struck by lightning and destroyed by the resulting fire. Carpenter, who was a man noted for his geniality and his unusual height, died prematurely of Bright’s disease in 1915.

At least four ropewalks have been documented in Portland in the early 19th century. The largest, the Hammond ropewalk, was on the shore of Back Cove on present-day Hammond Street. Built in 1804, the structure looked like a long tobacco shed and took up several blocks. It might have been the subject of Portland native and 19th-century poet Henry Wadsworth Longfellow’s poem, “The Ropewalk,” which begins:

In that building, long and low, / With its windows all a-row, / Like the port-holes of a hulk, / Human spiders spin and spin, / Backward down their threads so thin / Dropping, each a hempen bulk.

The Hammond ropewalk was destroyed by fire in 1846.

The new ropewalk was said to be the largest single wooden building in Maine—600 feet long and three stories high.

Bath had three known ropewalks, according to Maine Maritime Museum’s Lipfert. Two were 1,000 feet long, the third perhaps a couple of hundred feet. It’s thought the last one of the three burned down in the late 1800s. The head house of one still exists, converted into an apartment house and covered in vinyl siding. The building behind it is long gone.

Ropewalks existed as independent operations, similar to sail lofts, chandleries, and other ship-provisioning businesses. But mechanization required greater investment, likely phasing out small operations. Eventually, rope production moved to larger urban centers outside of Maine.

The use of plant-based cellulose fibers underwent a revolution mid-20th-century, with the invention of nylon. These days, ropewalks have given way to high-speed machinery with names such as dreff twisters and maypole braiders, operating with hypnotic efficiency. Still, like any invention that has met basic needs for millennia, the product remains essentially the same: a revolutionary tie that binds together all humanity.

Laurie Schreiber has written for newspapers and magazines on the coast of Maine for more than 20 years.

Yale Cordage twists a future

Tom Yale is shown here standing in a creel that holds hundreds of tubes of high-strength polyester ready to be twisted into strands that will be braided into hi-tech climbing lines for arborists. Photo by Bob Bukaty

A dull roar of machinery fills the cavernous Yale Cordage plant in Saco. Owner Tom Yale takes me onto the factory floor, where bobbins, spindles, and reels twirl, twine, and braid raw fiber into yarn and then into strands and then into finished products coiled in crates, ready to spool and ship to clients around the world.

He heads to the start of the production line where large machines called dreff twisters consume short fibers that resemble fuzzy entrails. These are combined with synthetic filaments with names like Kevlar, Technora, Vectran, and Spectra, and released as tightly twisted yarn, wound in neat packages on spools. This is only the start of a sequential process that turns raw synthetics into a rich repertoire of high-tech ropes. A finished spool weighs 20 pounds and contains a 15,000-yard-long strand of yarn.

A Yale employee checks a braider that

is making a climbing line called Hedra

for a British firm. Photo by Bob Bukaty

“Raw material comes in the form of dental floss, almost about the same size,” Yale yells, as I bend close to hear him. “Depending on the fiber, we can create a rope that is twice the strength of steel rod in the same diameter.”

Yale Cordage has been twisting raw materials into sturdy ropes of all sizes since its founding in 1950 by Tom Yale’s father, Sherman. Now the company specializes in synthetics and lines for specific users such as utility companies, the mining industry and boaters.

On the factory floor, the high-speed action that goes into twisting and braiding raw synthetics is hypnotic. A machine plies together multiple strands of line and feeds them into an up-twister. There, multiple packages are wound together onto ever-larger beams, whose strands feed through tensioners at a high rate of speed, into a machine that applies a proprietary protective coating and twists them, yet again, into larger-diameter yarns.

The adjacent section is noisier. Here, material from the twister bobbins is transferred onto braider bobbins, to achieve specific braids. Reels of yarn feed through spindles mounted on circular arrays that spin in opposite directions, the whole enclosed by metal-and-plexiglass cages. The spindles perform, essentially, a Maypole dance on what are, in fact, called maypole braiders. Braiders here are mounted with four-strand carriers, arrayed with spindles in multiples from 8 to 48. Surprisingly, the largest ropes come from the 8-strand carriers, and the finest from the 48.

Yale Cordage makes ropes that resist corrosive chemicals, can carry a million pounds or more, will not absorb water, won’t stretch, and can remain supple in extreme environmental conditions—all while being stronger and up to eight times lighter in weight than steel cable.

These are ropes that make hard jobs easier. The logging industry in the Pacific Northwest for example, has replaced some of its steel cables with lighter-weight synthetics for complex timber-harvesting and twitching operations. The lighter weight of the rope compared to steel has been crucial for safety.

During my visit, the 48-carrier machine was producing Kernmaster, a rope used principally in fire and rescue. Nearby, machines were making line for arborists, including a green-hued item called Poison Ivy and a pinkish counterpart named, naturally, Calamine.

Other dancing machines were turning out lines to be used by the power utility industry to string transmission wire and hoist poles; dielectric or insulator rope for live line work; data buoy mooring lines; electromechanical cables for anti-submarine warfare; faired cables for offshore seismic exploration; and plenty of rope for sailing yachts.

A recent project has been developing a special line that can resist shark bites. The rope will be used by NOAA on its network of storm-warning buoys, which must be able to endure deep-sea conditions, including predator bites. Yale tested the prototypes in an aquarium tank full of bull sharks. The test lines were baited to persuade the sharks to gnaw on them, Tom Yale said.

For thousands of years, rope was handmade from plant-based cellulose fibers such as hemp, sisal, and manila. Then in 1935, the chemical company DuPont developed nylon, the first synthetic fiber made through a chemical process.

Tom’s father, Sherman, was working for a multinational thread company when he started this company. During visits to Maine, where his wife’s family had property, Sherman noticed that lobster fishermen used tarred linen for heading twine on their traps. Although the tar helped the natural fiber last longer in the tough marine environment, he thought nylon would work better. In 1950, he bought a Wardwell rotary braider and some nylon from DuPont, set it up in his basement, and gave his product to local fishermen to test.

A worker loads line into a 12-strand

braider. Photo by Bob Bukaty

A couple of years later, Sherman retired from his day job, moved the family from North Carolina to Yarmouth, Maine, and went into business. Tom joined him in 1970 after graduating from the Florida Institute of Technology.

In 1972, the company was tiny, with annual sales hovering at $17,000. An avid sailor, Tom expanded the operation to produce rope for the yachting market and was among the first rope-makers to promote the use of Kevlar on high-performance sailboats.

“We owned the market for several years, producing mostly for very high-end racing boats,” Yale said. “Literally every boat, foreign or domestic, that competed in the America’s Cup up to 1983, and

Australia II, which won the cup that year, had Yale cordage on its boat.”

Now a multi-million-dollar company with plants in Saco, Maine, and North Carolina, Yale Cordage is on the cutting edge of synthetics for users such as power utilities, the mining industry, arborists, and national oceanographic programs such as the data and tsunami buoys deployed by the federal government. Sales today track at roughly $30 million.

“It’s exciting times,” said Yale, 67. “I should be winding down right now, and instead, I find myself winding up.”

—Laurie Schreiber

The crew at the Pleasant Street ropewalk in Castine. Photo courtesy Castine Historical Society

The crew at the Pleasant Street ropewalk in Castine. Photo courtesy Castine Historical Society  At one point the Castine Line & Twine Co. ropewalk on Water Street in Castine was said to be the largest single wooden building in Maine. It burned in 1913 after being struck by lightning. Courtesy Castine Historical Society Collections

At one point the Castine Line & Twine Co. ropewalk on Water Street in Castine was said to be the largest single wooden building in Maine. It burned in 1913 after being struck by lightning. Courtesy Castine Historical Society Collections

This ropewalk on Pleasant Street in Castine, built circa 1830, was near where the Maine Maritime Academy football field is today. In those days, rope was made in buildings that were as long as the line produced. Courtesy Penobscot Marine Museum

This ropewalk on Pleasant Street in Castine, built circa 1830, was near where the Maine Maritime Academy football field is today. In those days, rope was made in buildings that were as long as the line produced. Courtesy Penobscot Marine Museum  Tom Yale is shown here standing in a creel that holds hundreds of tubes of high-strength polyester ready to be twisted into strands that will be braided into hi-tech climbing lines for arborists. Photo by Bob Bukaty

Tom Yale is shown here standing in a creel that holds hundreds of tubes of high-strength polyester ready to be twisted into strands that will be braided into hi-tech climbing lines for arborists. Photo by Bob Bukaty

A Yale employee checks a braider that

is making a climbing line called Hedra

for a British firm. Photo by Bob Bukaty

A Yale employee checks a braider that

is making a climbing line called Hedra

for a British firm. Photo by Bob Bukaty

A worker loads line into a 12-strand

braider. Photo by Bob Bukaty

A worker loads line into a 12-strand

braider. Photo by Bob Bukaty